Photo credit: Hometown Organizing Project / cc

Workers throughout Alabama are reaching out to me to sound an alarm on what they are seeing inside meatpacking plants.This piece started out as an informative piece on how and why the COVID-19 virus is spreading rapidly through workers in these plants, but it has evolved into an investigative piece as well, about dangerous sanitary and environmental conditions affecting major meat suppliers in Alabama. Much of what you will read was a problem long before the COVID-19 pandemic.

Many U.S. citizens never put much thought into how things end up on the grocery shelves and in the coolers at our supermarkets. There’s this nebulous idea of meat packing plants, trucks, and stock clerks. We show up and the store bins of fruit and vegetables are filled and waiting for us, and the meat section has everything we want ready to go. The meat is packed neatly in plastic and styrofoam. We grab a pack of chicken, throw it in the cart, and move on.

The production and packing of meat for the public is greatly intertwined with the history of the United States and has led to great change in governmental policy, including the creation of entirely new departments. “The Jungle,” a 1906 novel by Upton Sinclair, described the industry in Chicago in brutal terms. It detailed the poor conditions of the workers in such stark ways that it inspired the creation of the Food and Drug Administration (FDA). According to the FDA’s website the department “is responsible for protecting the public health by ensuring the safety, efficacy, and security of human and veterinary drugs, biological products, and medical devices; and by ensuring the safety of our nation’s food supply”.

With the COVID-19 pandemic we may be on the precipice of such a moment once again.

I work with the nonprofit Hometown Organizing Project, part of the People's Action national network of grassroots groups, and we have spent the past weeks working in the rural areas of Alabama in support of the workers in these plants. We’ve learned a great deal about why plants are a perfect vector for this virus, and how hard it’s going to be to contain the virus while keeping these workers safe. This is a very real and present danger in many communities throughout the United States right now. There is great potential — and a near inevitability — for it to worsen in the coming days and weeks.

The Powder Keg

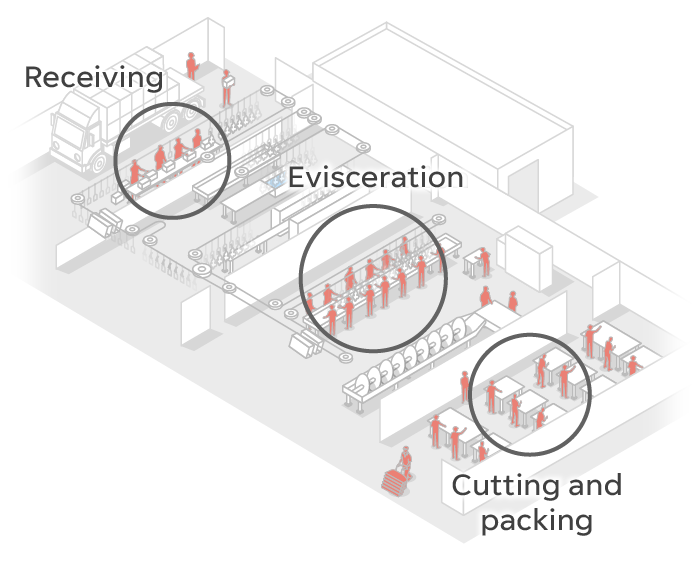

Below you see a typical setup in a plant. You’ll notice the close quarters and the fact that social distancing is impossible. A lot of plant floors are much larger than this example. These plants provide the perfect environment for transmission of highly contagious viruses. The environment is very cold, and workers just inches from each other can easily transmit the virus. By virtue of their setup, these plants were powder kegs just waiting for the spark that is the virus, Sars-Cov-2, better known as COVID-19.

A mask is one solution, but I have learned that some plants in our state aren’t supplying these and, if they are, the supply is inadequate. In fact, our organization has worked to draft hundreds of volunteer sewists in these areas to sew cloth masks for the workers in many plants. That is a stopgap at best. The Centers for Disease Control and Prevention (CDC) recommends masks in order to not spread the virus rather than a protection from the virus. We have to outfit every single worker with masks to slow the spread, and some of these communities have a dozen plants that run three shifts. They employ hundreds and hundreds of workers. This is no real answer to the fundamental issue of solving the current crisis within our plants and preventing these from becoming hot spots in a future pandemic.

Plant workers across 19 states had tested positive for the virus as of April 27th, according to the CDC. As of May 29th, there have been 44 deaths reported within the membership of United Food and Commercial Workers International, the largest union in the nation. As of the end of the month of May, the nonprofit group Food & Environment Reporting Network estimated that the number of workers infected with the virus is now more than 17,000, and 66 are dead.

The number of cases has grown tremendously since the first days of the outbreak, and the true numbers are not really known. One thing is certain, however. Workers are getting sick and dying from Covid-19 in these plants in numbers greater than any other work environment in the country.

In mid-April, USA Today investigative reporters found that the problem was drastically under-reported in the plants. According to their published article, “More than 150 of America’s largest meat processing plants operate in counties where the rate of coronavirus infection is already among the nation’s highest, based on the media outlets’ analysis of slaughterhouse locations and county-level COVID-19 infection rates.”

On April 28, President Donald Trump signed an executive order using the Defense Production Act to keep meatpacking plants open. The order declared our meat supply production critical. This has led to a number of workers coming in sick to avoid losing their jobs, and thereby infecting their co-workers. It also allowed major meat processing corporations to request waivers from the Department of Agriculture on how many birds workers can process in a minute.

United Food and Commercial Workers International Union issued a statement in response to the waivers saying, “These waivers guarantee that workers are more crowded along a meatpacking line and more workers are put at risk of either catching or spreading the virus.”

Many plants in Alabama, including those owned by Tyson Foods, Inc. and Wayne Farms, requested and received those waivers.

A Look Inside

I spoke with workers here in Alabama this week about the current conditions at their plants. They spoke on the condition of anonymity as they all fear losing their jobs. Some even risked their jobs to get pictures of the conditions in the plants to me. The plants require workers to leave their phone in their car when they arrive for work and phones are forbidden in work areas.

One plant employee told me, “We have no idea what is going on in here. Management tells us nothing. They’ve put up a few dividers and I see where they say they’re cleaning everything. They don’t keep us separated. We have 100 employees who ain’t showing up for work right now and no one knows if it’s because of the virus or that they’re scared of it. They are risking their jobs by staying home. Clean? I’ve been bitching about the conditions here forever. They ain’t cleaning nothing. You should see the bathrooms. People need to know what they’re seeing on tv is nothing like what goes on in a plant. We heard a Mexican man died on one of the other shifts. No one knows for sure.”

The employee texted me the following pictures on May 25th, 2020. This is the restroom at the plant for the workers on the floor. This same employee was sent for a test for Covid-19 on May 27th. They haven’t received the results of the test as of the time of publication of this article, and their plant is now a Covid-19 hot spot in their community.

Another worker in a different plant told me, “This virus is bad here but it has been bad in other ways for a while before this. The working conditions are bad in so many ways.”

A prime example of this occurred in August of 2018. During a fire at an Alabama plant the workers were sent to the parking lot for supervisors and administrators. The heat index was over 100 degrees. At many plants the workers park outside of the plant and have to go through security to get into work. The meat processing plants of Alabama are no different.

The employees were told to stay on the plant property until the fire was contained. The employees weren’t allowed access to their cars and were forced to wait for six hours outside. They were only allowed to go to their vehicles when the supervisors requested they retrieve their cell phones in order to use the flashlights on them to go back into the plant. The same phones that would have gotten them fired a day before were now being used in order to see to pack ice around the chicken that remained in the unaffected area of the plant- a plant that had no electrical power due to the fire.

“No one left because they told us we would be fired if we went to our car.”

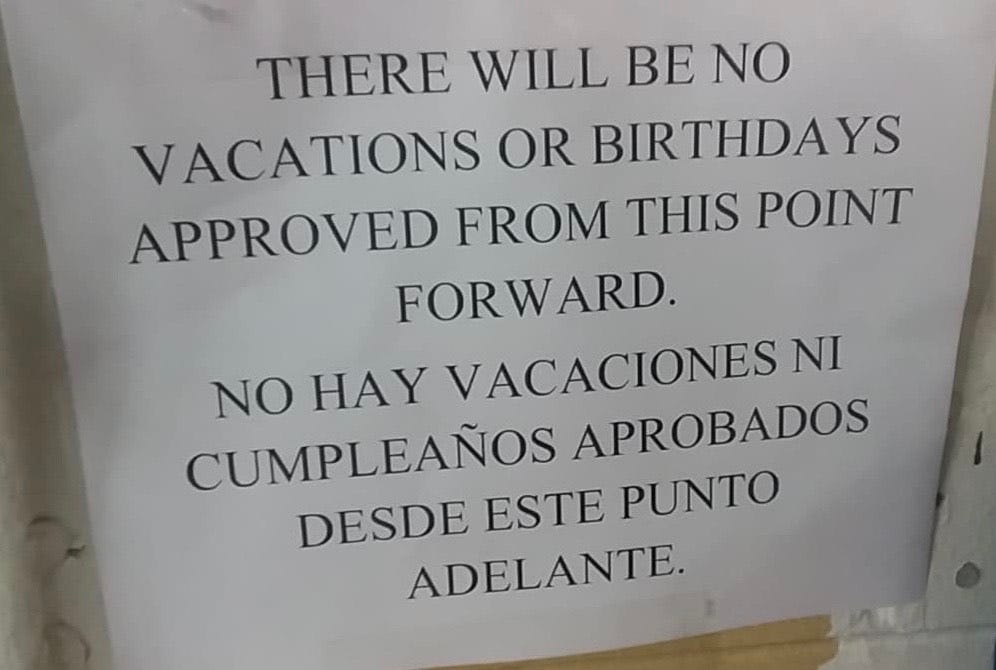

This type of treatment doesn’t surprise a lot of the workers I spoke with. Just this week the following was posted on a plant bulletin board. “Everyone knows we are in the middle of a pandemic but they didn’t explain anything to us. They just put it up. There’s little to no communication with the workers.”

In messages supplied to me, a plant maintenance worker writes, “There are dangerous boiler conditions. Storm drains outside run under the rechillers and drain directly to a creek. Vents blow all kinds of nasty stuff outside. The plant drains that run to the wastewater clogs frequently and the unclogged chicken waste on the floor ends up covered in flies and maggots.”

‘Years of issues’

Other plants in Alabama have far more issues than just these previous examples and the current crisis related to the pandemic.

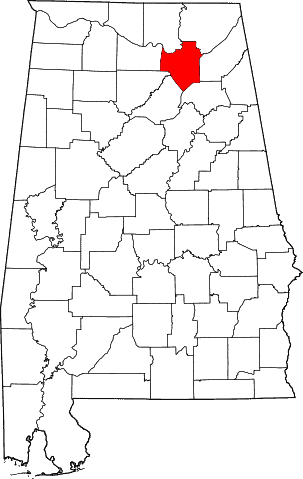

A plant owned by Tyson Foods, Inc. is facing a federal class action lawsuit due to a pipe failure at the Tyson in Hanceville, Alabama on June 6, 2019 that released partially treated sewage and wastewater into a neighboring waterway, killing an estimated 175,000 fish and sickening residents of the area.

Along with the federal class action suit, the Alabama Attorney General filed another suit on April 29th, 2020 on behalf of the State, Alabama Department of Environmental Management (ADEM) and Department of Conservation and Natural Resources (DCNR). A statement in the filing reads:

“On June 6, a pipe failure at the Tyson Plant in Hanceville, Alabama, caused the release of over 200,000 gallons of insufficiently-treated wastewater into the Mulberry Fork of the Black Warrior River. … This is a civil action against Tyson for violations of the Alabama Water Pollution Control Act (AWPCA) and the Alabama Environmental Management Act”

The suit went on to say “DMRs (Discharge Monitoring Reports) submitted to ADEM by Tyson indicate that it failed to properly monitor, and discharged and continues to discharge pollutants in violation of the limits imposed by Part I.A. of the NPDES (National Pollutant Discharge Elimination System) Permit(Emphasis mine- Author)

Before Tyson Foods, Inc. purchased the property in 2018, the same plant had spilled 80,000 gallons of wastewater in 2015 and 900 gallons of sulfuric acid that led to a fish kill along 7 miles of the river.

Edward F. Poolos, deputy commissioner of the Alabama Department of Conservation and Natural Resources, estimates that it will be about five years for nature to correct itself from the 2019 spill, as long as there are no more spills of toxic materials into the waterway during that time.

Tyson does have multiple plants, though they are only one company out of many throughout the state. Still, their environmental track record doesn’t lend itself to helping us trust the company when they claim they’re doing the best for their employees, and the general public, when it comes to Covid-19.

‘How Bad Is It?’

Knowing how bad this is in our meat processing industry in Alabama and elsewhere is tough. There are a couple of major contributing factors.

The first contributing factor is getting clear numbers and information from the plants. It took investigative reporting by news agencies such as USA Today to push some of the plants to acknowledge the issue publicly and implement mitigation measures to protect workers. Plants that were put in the headlines early in the pandemic, such as one owned by Wayne Farms in Marshall County Alabama, are now seeing cases and hospitalizations decrease.

AL.com reported on May 28 that Marshall County, a hot spot for the virus a month ago, now has a hospitalization rate of zero. Our organization focused efforts there over the past few weeks and managed to get thousands of masks into the plants. So far we have gotten masks to 3,200 of the 21,000 citizens in Albertville, Alabama, including 500 masks into the local hospital and over 1,000 into the Wayne Farms plant. Regardless, many more masks are on the way as the number of cases in is still concerning.

In Wayne Farms plants located in other counties, along with other manufacturers, the story is much different. In Bullock County, Alabama where Wayne Farms has a plant in Union Springs, the cases are currently growing every day. As of May 28 one of the highest rates of Covid-19 infection per capita in the state. In national news, a recent New York Times article describes the true numbers of sick workers in the plants around the United States as “elusive” due to many factors, including “the meat companies are not legally required to disclose how many workers are sick.”

These plants are often staffed by numerous undocumented workers, who have no insurance and little to no support network. That is the second contributing factor that prevents us from getting a solid idea of the breadth of this crisis. I’ve spoken with undocumented workers who have been symptomatic and continued going to work. “We have no $1200 (stimulus) check coming and the plants are open. People have to make money somehow when their children are going hungry”, one worker told me. A lot of plants are now checking the temperature of workers going into their plant, but that doesn’t account for the asymptomatic carriers who can still spread the virus. Undocumented workers fearing deportation or the loss of their job have avoided medical care in some instances.

As a result there has been a backlash against these workers in places, with reports of businesses refusing to serve latino workers in Iowa because they were thought to have Covid-19, as well as Wisconsin Supreme Court Chief Justice Patience Roggensack saying, “These (cases of covid-19) were due to the meatpacking, though… It wasn’t just the regular folks in Brown County.” Headlines now read “Some blame meatpacking workers, not plants, for virus spread”.

These discriminatory actions, words, and beliefs are coupled to a misdirected ire.

Along with Covid-19, meatpacking plants have long had numerous issues nationwide, especially when it comes to serious injuries. Many injuries go unreported or, in the case of House of Raeford Farms in North Carolina, are filed in a way to mislead regulators. A 2008 investigation by The Charlotte Observer found a House of Raeford Farms plant maintained a clean safety record by bringing employees back into the plant within hours of having surgery.

The investigation also revealed that this same plant had 130 severe safety violations from years 2000 to 2008.

The associated article describes the working conditions within the plants:

“Poultry plants are filled with hazards. On one side of the factory, employees grab live birds before hanging them upside down on moving hooks that whisk them off for slaughter. On the other side — after the birds are scalded, plucked and chilled — they’re hurried along production lines where workers stand shoulder-to-shoulder wielding blades for hours with few breaks.Temperatures hover near freezing to prevent the spread of bacteria. Water drips off machinery, falling onto floors slick with chicken fat. The din of clanking conveyor belts makes conversation nearly impossible.”

The plants were dangerous long before Covid-19, and the virus makes an already hazardous work situation even worse.

The high number of immigrants working in the meatpacking plants is due to an overt effort by the industry in the 1990s when they actively pursued undocumented worker hires in South Florida and Central America. This allowed the plants to avoid paying higher wages to workers who were trying to unionize. Busloads of workers were brought in from those areas and it became an open secret within the industry. By taking advantage of those seeking a better life for themselves and their families, the plants were able to save on labor costs and prevent unionization in their facilities. This practice started in Mississippi, but it has spread throughout the United States.

In August of 2019 Immigration and Customs Enforcement (ICE) raided the plants in Mississippi and arrested 680 undocumented workers. Many of them had children born and raised in the United States in the years since their arrival to work in the plants. Families were torn apart with children coming home to no parents the day of the raids. The impoverished communities were still reeling from the raids when the pandemic hit.

The burden of solving the Covid-19 crisis within plants is on the plant owners. They alone are responsible for the circumstances that have exacerbated the current crisis. The government’s executive orders keeping the plants open and allowing for waivers that endanger the workers has been an extreme mitigating factor as well. As for the plant workers, they need our support at this time and not blame for the crisis within the plants.

What Can We Do?’

This COVID-19 pandemic has laid bare failures in our systems in the United States, while also exposing and reminding us of other issues in our society related to worker’s rights and environmental issues. There’s a needed conversation to be had about these things — and a great deal of action as a result — but right now people are having to focus on filling the gaps that have come about as a result of those systemic failures during this pandemic.

The COVID-19 crisis within meatpacking plants is not exclusive to Alabama. It is an issue from sea to shining sea in the United States in hundreds of rural communities.

Over the past few weeks groups of women in Alabama have produced and distributed tens of thousands of masks all over the state through our organization. They have supplied plants, hospitals, pharmacies and immunocompromised individuals. When the PPE and mask shortage hit, volunteers stepped up to fill the gaps here. This is true all over the United States.

Food banks have been set up to supplement the existing food pantries in larger towns and cities, and in rural areas where resources are scarce. Worker support funds for unemployed workers have also started in multiple cities here in Alabama.

If you are looking at how to help where you live, I suggest finding a local nonprofit working in mutual aid efforts in your area and see where you can plug in. Specifically you should seek out those who have been working within the communities you want to serve and let them inform you of the needs there and how you can be of support. The one thing we can control right now is helping take care of our fellow residents in our home areas.

We currently have multiple mutual aid efforts directed to helping the workers in these plants and in their communities in Alabama, along with relief projects for individuals struggling during the pandemic.

There are no easy answers to the myriad of problems the United States is now facing. But staying informed and getting actively involved in your local area is key to seeking fundamental changes that will both solve current issues as well as address the systemic issues that underpin these problems we face as a society.

For more information about our organization, Hometown Organizing Project, click here and sign up to get involved, or email the author at warren@hometownorganizing.org